Category 1 Vibration Analysis Training April 28 – May 1, 2026 – Failure Prevention Associates

Day 1: Vibration Science: Duration : 8am – 5pm

Condition based monitoring programs

Review of basic vibration analysis science

Review basic machine faults

Fourier Transform Spectrum analysis

Recognition of poor data

Waveform and Spectrum Graph analysis

Demodulation & other specialized spectra analysis

Day 2: Practical Field Analysis Duration : 8am – 5pm

Phase analysis for field applications:

Unbalance, Eccentricity, Bent Shaft, Misalignment, Soft Foot, Resonance

Introduction to Field balancing

Hands-on Workshop practicing phase analysis

Bump testing for Resonance evaluation

Vibration analysis case studies

Day 3: Vibration Practical Data Collection & Analysis Duration : 8am – 5pm

Vibration Acceptance Testing

Building an initial machine configuration

Setting up a Route

Vibration Data Collection & Analysis Practical

Making a call in the field

Day 4: Vibration Certification Level 1 Testing

Testing for certification 8am- 11am

Testing for ASNT or ISO certification

Vibration Analysis Training

Vibration Analysis Training at Failure Prevention Associates is the only U.S. program taught by an ASNT PdM Level III instructor with dual endorsement in Vibration Analysis AND Thermal/Infrared Testing.

This ISO 18436-2 compliant training certifies Category I and Category II analysts using hands-on instruction in our Houston-area mill test lab—the only U.S. facility with dynamic rotating equipment for live fault diagnosis practice.

Why Attend Our Training Courses?

Vibration Analysis is an important tool in an overall predictive maintenance program. Vibration data collected by properly trained analysts can be used to diagnose many types of problems in all types of industrial machinery.

Vibration analysis can be used to find both major and minor problems before they result in costly downtime or catastrophic failures.

What You Can Expect in Our Vibration Analysis Courses

- Condition monitoring program

- Review of basic vibration analysis science

- Review of basic machine faults

- Fourier Transform Spectrum analysis

- Recognition of poor data

- Waveform and spectrum graph analysis

- Demodulation and specialized spectra analysis

- Phase analysis for field applications

- Unbalance, eccentricity, bent shaft, misalignment, soft foot, resonance

- Introduction to field balancing

- Hands-on workshop for phase analysis

- Bump testing for resonance evaluation

- Vibration analysis case studies

- Vibration acceptance testing

- Building initial machine configuration

- Setting up a route

- Vibration measurement, data collection, and analysis practical

- Course materials and reference manual provided

Prerequisites

A working knowledge of mechanical equipment is recommended. No prior vibration analysis experience is required.

Who Should Attend?

This course is designed for individuals who want to learn basic vibration analysis on industrial machinery.

Participants will gain skills in vibration data collection, analysis, and reporting.

Vibration analysts, mechanical technicians, engineers, and maintenance personnel will benefit from this course.

Vibration Analyst Certification Exam (CAT I)

To become a CAT I Vibration Analyst, candidates must complete the class, pass the exam, and have at least 6 months of experience.

If experience requirements are not met, a provisional certificate will be issued. Candidates will have one year to complete the required experience.

Vibration Analyst Certification Exam (CAT II)

CAT II candidates must have at least 18 months of cumulative experience.

To enroll, candidates must have at least 6 months of experience and have passed the CAT I exam.

Provisional certification is available until experience requirements are fulfilled.

Vibration Analyst Re-Certification

ISO standards require recertification every five years through re-examination or renewal.

Renewal requires evidence of continued professional work and study. The renewal fee is $250.

Why This Training Matters

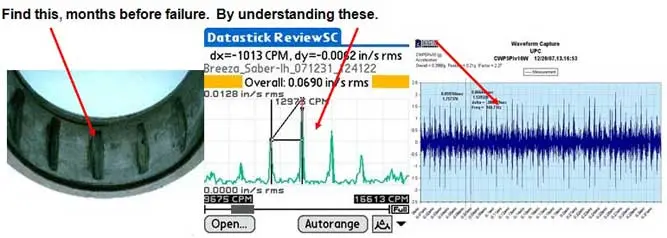

By viewing vibration graphs, analysts can detect equipment problems months or years before failure.

While vibration analysis may seem complex, our instructors make it easy to understand.

FPA’s training helps you identify bearing faults and other issues long before failure occurs.

Recent Comments