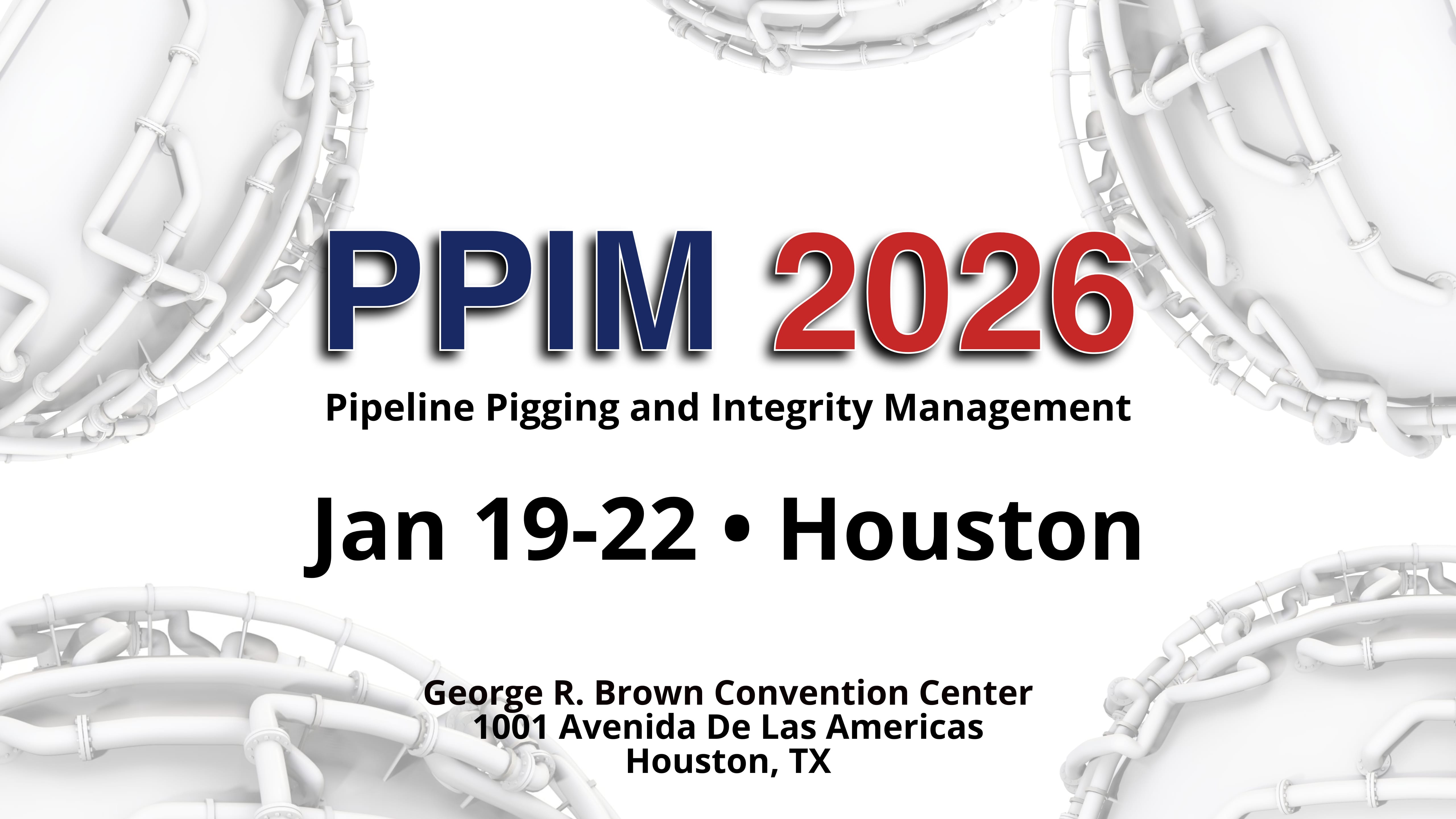

FREE Passes for 2026 PPIM Conference the 38th Annual Pipeline Pigging & Integrity Management Show Jan 19-Jan 22, 2026 – Houston

This Event Reminder / Save The Date is Sponsored by: State Service, leaders in pipeline pigging and chemical cleaning

FREE Passes for PAH Member – Click the link to register.

The industry forum devoted exclusively to pigging for pipeline maintenance and inspection, engineering assessment, repair, risk management and NDE.

Since 1989, attendance at the annual PPIM Conference and Exhibition in Houston has grown from a few hundred to more than 4,000,

including a commercial exhibition that began with a handful of specialized solution providers and now involves more than 190 companies

and industry organizations from over 25 countries.

PPIM is an international forum focused on engineering and technology for onshore & subsea pipeline inspection, assessment and repair, as well as regulatory compliance and Integrity Management Programs.

Broadly, our primary criteria for selection of papers to be presented at PPIM are:

*Operator involvement and/or real-world experience;

*Technical not commercial (and technically sound);

*Respected author/institutions;

*Broad appeal and/or novel/new technologies.

PPIM draws more than 3000 engineering management and field operating personnel from pipeline transmission and distribution companies, service companies and equipment providers concerned with improved operations and integrity management in the transportation of natural gas, crude oil, refined products, LNG, RNG, LPG, CO2 and hydrogen.

Papers will be published and distributed to the conference delegates in encrypted PDF format. In addition, PPIM conference papers will be incorporated in the SCOPUS® abstract & citation database which is used by leading academic, business, and government institutions. Individual papers will also be freely available to these institutions in order to promote citation and reference.

Schedule at a Glance:

COURSES

January 19-20, 2026

CONFERENCE

January 21-22, 2026

EXHIBITION

January 20-22, 2026

WELCOME

In parallel with the demands for greater pipeline safety, reliability, and efficiency – and the explosive growth in the market for technologies

to help meet those demands – PPIM has evolved to become the industry’s primary forum for reporting new developments and field experience,

and for showcasing the relevant tools and systems. It is the place where the needs of pipeline operators and the capabilities of service and

equipment suppliers intersect.

Information exchange at PPIM is supported by a range of educational technical courses that take place in advance of the conference and exhibition.

Led by a distinguished faculty including the world’s top experts, the courses provide a foundation for well-informed inquiry and dialogue among

industry colleagues, clients, and contractors.

We take great pride in the fact that more than 60% of our conference participants are repeat attenders and more than 90% of our exhibitors

return each year. We hope you’ll be among them at PPIM 2026 and look forward to seeing you there.

What is the Schedule for the 2026 PPIM Pipeline Pigging and Integrity Conference?

SUNDAY, JANUARY 18

10:00 a.m. – 4:00 p.m. – Early move-in (by appointment only)

MONDAY, JANUARY 19

7:00 a.m. – 6:00 p.m. – General move-in and installation

TUESDAY, JANUARY 20

7:00 a.m. – 3:00 p.m. – General move-in and installation

5:00 p.m. – 7:00 p.m. – Opening reception

WEDNESDAY, JANUARY 21

9:00 a.m. – 6:30 p.m. – Exhibits open

4:30 p.m. – 6:30 p.m. – Reception

THURSDAY, JANUARY 22

9:00 a.m. – 2:00 p.m. – Exhibits open

2:00 p.m. – 10:00 p.m. – Teardown and move-out

EXHIBITION SCHEDULE

- Between 5:00 p.m. and 8:00 p.m. – Tuesday, January 20

- Before 7:30 p.m. – Wednesday, January 21

- Before 2:00 p.m. – Thursday, January 22

INSTALLATION AND TEARDOWN

All exhibitor displays must be completely installed by no later than 3:00 p.m. Tuesday, January 20, 2026.

Exhibitors may not begin dismantling before 2:00 p.m. on Thursday, January 22, 2026.

Hospitality suites, demonstrations, and related events: Exhibitors agree not to host or schedule activities outside of the exhibition area

that are related to conference attendees during official conference hours.

2026 Pipeline Integrity Conference

Wednesday, January 21, 2026

7:00 Breakfast & Registration open

| 1.0 Plenary – Opening Session | ||||

| 8:00 | Opening remarks | |||

| 8:05 |

205 Ten-Year Analysis of Reportable Pipeline Accidents: Trends, Risk Factors, and Lessons Learned |

|||

| 8:35 | Young Pipeline Professional Annual Recognition Award Presentation | |||

| 8:50 |

186 Talent pipeline – A Comprehensive Review of the Talent Management and Career Journeys in the Pipeline Industry |

|||

| 9:20 |

154 Has the Industry Forgotten How to Weld? |

|||

| 9:50 | Refreshment Break | |||

| 10:50 |

State of the Industry Report |

|||

| 11:05 |

250 An Improved Fracture Model for Assessing Crack-Like Flaws in Pipelines |

|||

| 11:35 |

231 An Operator’s Practical Approach for Evaluating and Prioritizing ILI-Reported Dents |

|||

| 12:05 |

124 Advances in API 1163 Level 3 ILI Validations |

|||

| 12:35 | Lunch in the Exhibition Hall | |||

| Room A | Room B | Room C | Room D | |

| 1.1 Unpiggable or Difficult-to-Inspect 1 | 2.1 Geohazards 1 | 3.1 Cracks | 4.1 Corrosion | |

| Session chair: | Session chair: | Session chair: | Session chair: | |

| 2:00 |

115 Predicting Corrosion Severity on ILI Remnant Pipe Using Extreme Value Analysis |

168 A Deep-Dive into the PHMSA Significant Incident Database and What it Tells us About Trends in Pipeline Geohazards |

130 Longitudinally Misaligned Pipeline Stacked Crack Interaction Using 3-D Crack Meshes – Part II |

255 Joint-Based versus Segment-Based CGRs – A Case Study |

| 2:30 |

189 Robotic Inline Inspection for Critical Gas Distribution Infrastructure |

267 Automated and Continuous Evaluation and Ranking of Geohazards by Comparing Bending Strain Features Against Geohazard Inventory and Inspection Records |

200 Finding the Edge of Crack & Seam Welds in the Field with Direct High-Resolution ILI Measurements |

296 Even Faster Effective Area Method: Further Optimization of the Effective Area Method for Plausible Profile Corrosion Assessments |

| 3:00 |

284 Advancing Seam Integrity on Difficult to Inspect Pipelines: Robotic Inspection of Vintage ERW Pipeline for SSWC, Lack of Fusion, and other Longitudinal Weld Anomalies |

163 When Did the Slope Start Moving … Varved Clays, Pipelines, and Landslides |

144 Development and Implementation of a State-of-the-Art Seam Weld Fatigue Cracking Integrity Management Program |

209 Bridging Overline Surveys and ILI Tools with Corrosion Computer Modeling |

| Room A | Room B | Room C | Room D | |

|

1.2 Unpiggable or Difficult-to-Inspect 2 |

2.2 Circumferential Stress Corrosion Cracking | 3.2 Materials Testing & Verification 1 | 4.2 Integrity Management 1 | |

| Session chair: | Session chair: | Session chair: | Session chair: | |

| 3:30 |

192 Managing Internal Corrosion Threat in Unpiggable Pipelines and Facility Deadlegs: An Update on Industry Standards and What the Data Tells Us |

254 Screening and Assessment of Circumferential SCC in Pipelines – Comparison of Stress- and Strain-Based Approaches |

242 Field Simulation Material Property Verification Trial |

166 A Primer on The Hazard Posed by Agricultural Tilling to Buried Pipelines |

| 4:00 |

164 From Prediction to Proof: Leveraging ILI to Validate a Non-Intrusive Pipeline Assessment Framework |

114 Testing and Validation Methodologies of MFL ILI Technologies for the Detection of CSCC and Off-Axis Cracks and Crack-like Features |

139 Using Composition Data to Improve the Accuracy of Nondestructive Strength Estimates |

243 The LTS Futures Project – An Update of a UK Operator’s (SGN) Experience of Assessing the Feasibility of Repurposing their Natural Gas Transmission System to Transport Hydrogen |

| 4:30 | Conference Day 1 concludes | |||

| 4:30 – 6:30 Reception in the Exhibition Hall | ||||

2026 – Thursday, January 22

| Time | Room A 1.1 Unpiggable or Difficult-to-Inspect 1 Session chair: |

Room B 2.1 Geohazards 1 Session chair: |

Room C 3.1 Cracks Session chair: |

Room D 4.1 Corrosion Session chair: |

|---|---|---|---|---|

| 2:00 |

115

Predicting Corrosion Severity on ILI Remnant Pipe Using Extreme Value Analysis

|

168

A Deep-Dive into the PHMSA Significant Incident Database and What it Tells us About Trends in Pipeline Geohazards

|

130

Longitudinally Misaligned Pipeline Stacked Crack Interaction Using 3-D Crack Meshes – Part II

|

255

Joint-Based versus Segment-Based CGRs – A Case Study

|

| 2:30 |

189

Robotic Inline Inspection for Critical Gas Distribution Infrastructure

|

267

Automated and Continuous Evaluation and Ranking of Geohazards by Comparing Bending Strain Features Against Geohazard Inventory and Inspection Records

|

200

Finding the Edge of Crack & Seam Welds in the Field with Direct High-Resolution ILI Measurements

|

296

Even Faster Effective Area Method: Further Optimization of the Effective Area Method for Plausible Profile Corrosion Assessments

|

| 3:00 |

284

Advancing Seam Integrity on Difficult to Inspect Pipelines: Robotic Inspection of Vintage ERW Pipeline for SSWC, Lack of Fusion, and other Longitudinal Weld Anomalies

|

163

When Did the Slope Start Moving … Varved Clays, Pipelines, and Landslides

|

144

Development and Implementation of a State-of-the-Art Seam Weld Fatigue Cracking Integrity Management Program

|

209

Bridging Overline Surveys and ILI Tools with Corrosion Computer Modeling

|

Session Block 2Room A: 1.2 Unpiggable or Difficult-to-Inspect 2

Room B: 2.2 Circumferential Stress Corrosion Cracking

Room C: 3.2 Materials Testing & Verification 1

Room D: 4.2 Integrity Management 1

Session chairs: Room A: _____, Room B: _____, Room C: _____, Room D: _____

|

||||

| 3:30 |

192

Managing Internal Corrosion Threat in Unpiggable Pipelines and Facility Deadlegs: An Update on Industry Standards and What the Data Tells Us

|

254

Screening and Assessment of Circumferential SCC in Pipelines – Comparison of Stress- and Strain-Based Approaches

|

242

Field Simulation Material Property Verification Trial

|

166

A Primer on The Hazard Posed by Agricultural Tilling to Buried Pipelines

|

| 4:00 |

164

From Prediction to Proof: Leveraging ILI to Validate a Non-Intrusive Pipeline Assessment Framework

|

114

Testing and Validation Methodologies of MFL ILI Technologies for the Detection of CSCC and Off-Axis Cracks and Crack-like Features

|

139

Using Composition Data to Improve the Accuracy of Nondestructive Strength Estimates

|

243

The LTS Futures Project – An Update of a UK Operator’s (SGN) Experience of Assessing the Feasibility of Repurposing their Natural Gas Transmission System to Transport Hydrogen

|

| 4:30 | Conference Day 1 concludes | |||

| 4:30 – 6:30 | Reception in the Exhibition Hall | |||

This is the 2026 PPIM Schedule as of Jan 1, 2026 and the PPIM Papers that will be presented. The 2026 PPIM Conference location will be at George R Brown Convention Center in Houston Texas.

Recent Comments