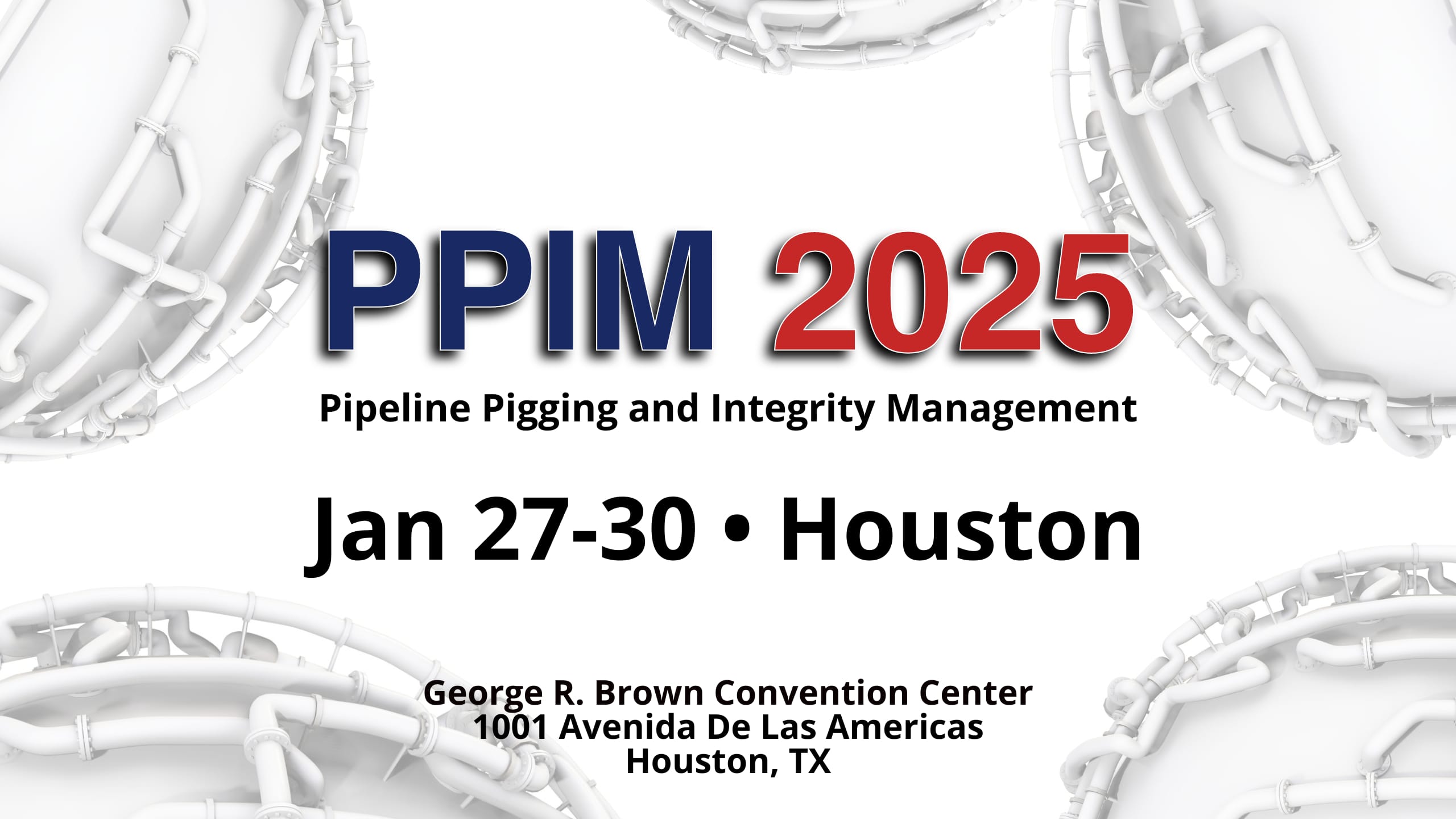

FREE Passes for PAH Members: Conference Agenda Now Out for 2025 PPIM – The 37th International Pipeline Pigging and Integrity Management Conference will take place in Houston on January 27-January 30, 2025

This Event Reminder / Save The Date is Sponsored by: State Service, leaders in pipeline pigging and chemical cleaning

We Save Major Industry Dates We put up event reminders as a courtesy of the Non-Profit and Trade Organizations we support.

THE 37th INTERNATIONAL Pipeline Pigging & Integrity Management Conference™ plus Training Courses and Exhibition

Located at George R. Brown Convention Center and the Hilton Americas1001 Avenida De Las Americas, Houston, TX 77010

COURSES

January 27-28

CONFERENCE

January 29-31

EXHIBITION hours

Tuesday, January 28

5:00pm-7:00pm Opening reception, Exhibition open

5:00pm-7:00pm Reception, Exhibition open

Wednesday, January 29

9:00am-7:00pm Exhibition open

Thursday, January 30

9:00am-2:00pm Exhibition open

PPIM : The industry forum devoted exclusively to pigging for pipeline maintenance and inspection, engineering assessment, repair, risk management and NDE.

Discover the Pipeline Pigging and Integrity Management Show

Are you invested in the operation and maintenance of pipelines? Do you want to stay up to date with the latest advancements in pipeline pigging and integrity management? Look no further than the Pipeline Pigging and Integrity Management Show 2025, the premier event for professionals in the pipeline industry. Here we will explore what this show is all about and what you can expect when attending.

About the Show:

The Pipeline Pigging and Integrity Management Show is an annual event that brings together industry experts, professionals, and organizations who are passionate about pipeline maintenance and safety. This show serves as a platform for showcasing and discussing innovative technologies, best practices, and solutions related to pipeline pigging and integrity management.

What to Expect:

When attending the show, you can expect to be immersed in a world of knowledge and cutting-edge advancements. Educational sessions, presentations, and exhibitions will provide you with the opportunity to learn about the latest trends and developments in pipeline pigging and integrity management. Discover state-of-the-art equipment, services, and software that are designed to enhance pipeline maintenance and safety.

Networking Opportunities:

The Pipeline Pigging and Integrity Management Show goes beyond just educational sessions and exhibitions. It also fosters networking among industry experts, allowing for valuable knowledge sharing and collaboration. Connect with like-minded professionals, exchange ideas, and build relationships in a supportive and collaborative environment.

See You There:

The Pipeline Pigging and Integrity Management Show is a must-attend event for professionals involved in the operation and maintenance of pipelines. By participating in this show, you will gain valuable insights into the latest advancements in pipeline pigging and integrity management. Take advantage of the educational sessions, exhibitions, and networking opportunities to enhance your knowledge and expand your professional network. Mark your calendars and don’t miss out on this incredible opportunity to propel your career forward in the pipeline industry.

If you are looking to know more about the 2025 PPIM, here is the agenda for the upcoming conference.

If you are a Pipeliners Association of Houston Member, you get free access

Tuesday & Wednesday

| 7:00 | Breakfast sponsored by Inline |

| 7:00 | Registration open |

| 1.0 Plenary – Opening Session sponsored by NDT Global | |

| 8:00 | Opening remarks |

| 8:15 | 215 State of Integrity 2025 – Sheri Bacoum, OneBridge Solutions, Inc., Durango, USA |

| 8:45 | Young Pipeline Professional Annual Recognition Award Presentation |

| 9:00 | 217 Managing the Pipe Body Hard Spots Integrity Threat Michael Rosenfeld, Bill Amend, Simon Slater RSI Pipeline Solutions, New Albany, USA, ROSEN Group, Columbus, USA |

| 9:30 | 167 Practical Challenges of Using the RP 1183 Shape Parameter Methods Rhett Dotson, Brian Leis Integrity, Houston, USA; N Leis, Consultant, Inc., Columbus, USA |

| 10:00 | Refreshment Break |

| 11:00 | 179 The Sky Is Not Falling — Mechanical Damage Can Be Assessed Appropriately Amro Rana, Sanjay Tiku, Al Rostaoei, Behrooz Sharif, Vlado Semiga, Aaron Dinwittzer, Munendra Tomar, Yohan Miglis, Mark Piazza Enbridge, Ottawa, Canada; ADM Consulting, Ottawa, Canada; TC Energy, Houston, USA; Kinder Morgan, Houston, USA; American Petroleum Institute, Washington DC, USA |

| 11:30 | 280 Lessons Learned Using API 1163 for Metal-Loss ILI Tom Bubbenk, Matt Ellinger DNV, Dublin, USA |

| 12:00 | 161 Leveraging Destructive Testing to Enhance Detection and Identification of Complex Cracking in LF-ERW: Case Study Phase II Christopher Newton, Jordi Aymerich, Sayan Pipattan, Tania Haro, Santiago Urrea, Alex Hersley Phillips 66, Houston, USA; NDT Global, Calgary, Canada; NDT Global, Stutensee, Germany; NDT Global, Houston, USA |

| 12:30 | Lunch sponsored by ENDURO |

| 14:00 – 15:00 | Room A: 295 Highlighting the Threat of Circumferential Stress Corrosion Cracking (CSCC) with Advanced In-Line Inspection Tools Matt Monberg, Jonathan Hardy, Dane Butler, TD Williamson, Houston, USA |

| Room B: 176 Development and Implementation of a Compact 36-Inch Combination Ultrasonic ILI Tool for Enhanced Pipeline Integrity Nathan Leslie, Jake Hoase, Jonas Butterer NDT Global, Houston, USA; Colonial Pipeline Company, Alpharetta, USA; NDT Global, Stutensee, Germany |

|

| Room C: 261 Identification of Factors to Determine Statistically Appropriate and Conservative CVN Toughness Values for Transmission Pipelines Brett Davis, Brian Patrick, Lily Wang, Heather Watson, Reid Tait Pacific Gas & Electric Company, San Ramon, USA; Exponent, Inc., Philadelphia, USA |

|

| Room D: 271 A Case Study of a Riverbank and Riverbed Armoring and Regarding Geohazard Remediation Eric Jenkins, Stella Cunha Tetra Tech, Denver, USA; Enbridge, Calgary, Canada |

|

| 14:30 | Room A: 288 Detection and Sizing of SCC in Seam Welds of Pipelines with ILI/EMAT Advanced Ultrasonic Imaging Niels Rodrigto Applus-RTD, Rotterdam, Netherlands |

| Room B: 229 Overcoming Operational Obstacles: A Collaborative Approach to In-Line Inspection of a Unique Mexican Gas Pipeline McKenzie Kissel, Keila Cariadd, Aaron Scharitz, Neil Short, Ricardo Vazquez, Pu Gong, Stephen Westwood TC Energy, Mexico City, Mexico; TC Energy, Calgary, Canada |

|

| Room C: 297 Temperature to Support Fully Baking Pipeline FCS Crack Initiative Fan Zhang Phillips 66, Houston, USA |

|

| Room D: 182 Axial Strain Evaluation and Integration into Geohazard Management Programs Jeff Hafer, Sylvain Cornu Marathon Pipe Line, USA; NDT Global, Stutensee, Germany |

|

| 15:00 | Refreshment Break |

| Afternoon Sessions: | |

| 16:30 | Room A: 245 Compression Sleeves – A Pragmatic Approach to Managing Design Variables and Constraints Atul Gangotir, Ahmed Hosaini, Matt Jouhani ADV Integrity Inc., Magnolia, USA; Bechel Energy, Houston, USA |

| Room B: 220 Leveraging Validation Data to Improve ILI Performance for SSCC Christopher Davies, Johannes Spille, Simon Slater ROSEN Group, Houston, USA |

|

| Room C: 140 Remaining Life Assessment of Hydrogen Pipelines for Flaw Sizes Below ILI and NDE Detection Limits Zahra Lotfoll, Michel Brongers Kiefner and Associates Inc., Houston, USA; Kiefner and Associates Inc., Columbus, USA |

|

| Room D: 106 Guided Wave Quantitative Contact Corrosion Measurement Rhett O’Brian GUL Americas, Houston, USA |

|

| 17:30 | Conference Day 1 concludes |

| 17:30 | Reception sponsored by Intero |

Thursday

| 7:00 | Breakfast |

| 7:00 | Registration open |

| Morning Sessions | |

| 8:00 | Room A: 200 Probabilistic Assessment of Cracked Seam Welds: Advanced Insights Revealed Through Case Studies Benjamin Novak, Therese Jensen Enbridge, Integrity Engineering, Edmonton, CanadaRoom B: 213 Four Plans Are Costing More Simon Roberts, Christopher Powers ROSEN Group, Houston, USA; Williams Gulf Coast, Katy, USARoom C: 220 Addressing Dents in Pipelines: Where Are Industry Standards Lacking? Michael Kubelka, Arvind Tiwari TC Energy, Toronto, CanadaRoom D: 299 Stress Relief Cracking Phenomena in Welded Components of Pipelines Amir Ahour, Randall Palermo Enbridge, Calgary, Canada |

| 8:30 | Room A: 225 EMAT Technology for Crack Detection in Gas Pipelines Thomas Rinker, Rakesh Rao ROSEN Group, USARoom B: 294 Minimum Requirements for Tools in Heavy Seam Weld Discovery Smith Associates, Fairfax, USARoom C: 244 Creating Dent Strain Maps for Integrity Verification Hangit Fu, Joy Winston ROSEN Group, Calgary, CanadaRoom D: 259 Multi-Dimensional Analysis Frameworks Randall Shehan Enbridge, Calgary, Canada |

| 9:00 | Room A: 187 Exam Grades MP Elevations in High-Pressure Pipelines Xavier Grant Imperial Oil, Calgary, CanadaRoom B: 234 Integrity Work Assessments and Pipeline Planning David Spencer, Tom Gilmat SafetyNet Integrities, Houston, USARoom C: 290 Simulation Techniques in Pipeline Dent Assessment Gerald Phillips API Dynamics, USARoom D: Insights into Geohazard Mapping Frameworks Steven Crosby Calgary, Canada |

| 9:30 | Refreshment Break |

| 10:30 | Room A: 295 Validating Crack Inspection in Welds Tom Bubbenk, Matt Ellinger DNV, Dublin, USARoom B: 136 Lifespan Planning for Pipeline Integrity Thomas Bergman, Neil Gibbs TD Williamson, USARoom C: 290 Simulation Methodology for Assessing Weld Stress Colin Farrell, Guillermo Patel API Dynamics, Calgary, CanadaRoom D: 111 Subsea Imaging and Detection Accuracy Studies Apollo Ventures, Norway |

| 11:00 | Room A: 117 API 579-1/ASME FFS-1 Fatigue Analysis for Pipeline Cracks Samuel Carter, Greg Milton Integrity Partners, Houston, USARoom B: 218 Managing Subsea Cracks for Pipeline Safety Sarah Collins, Adrian Wright Integrity Systems, AustraliaRoom C: 266 Advanced Dent Assessment Methodologies Murtaza Karam, Annette George TransCanada Pipelines, USARoom D: 228 Seamless Subsea Mapping Algorithms Peter Glenwright HydroMaritime, Canada |

| 12:00 | Lunch |

| 13:30 | Room A: 142 Lessons Learned from Stress Corrosion Pipeline Challenges Robert Smith Pipeline Integrity, Alberta, CanadaRoom B: 239 Predictive GIS Monitoring for Hot Zones Rafael Villas Integrity HoustonRoom C: 241 Inspection Strategies for Pipeline Rehabilitation Margaret Foster Technical Integrity Services, USARoom D: 177 Risk Modelling for Pipeline Rehabilitation Programs Alex Schneider Enbridge, Canada |

| 14:00 | Room A: 293 Repair-by-Repair Lessons for Pipeline Seam Cracks David Russell, Susan Moran Williams Energy, Dallas, USARoom B: 285 Comparative Study of CRAs and Failure Modes Adam Joseph, Ryan Keyes Steel Tech Solutions, Ontario, USARoom C: 156 Advanced Tools for High-Pressure Pipeline Repairs M.L. Hudson Energy FlowCaps, Houston, USARoom D: 198 3D Imaging-Based Condition Assessments for Pipe lines Arnold Fitzgerald Matt Research xSolutions |

| 15:30 | Refreshment Break |

| 16:30 | Room A: 164 Can AI Lead in Fatigue-Life Estimation of Flexible Pipelines? Russell Clark Advanced FPS Services Inc., USARoom B: 257 Deepwater Testing of High-Pressure Guided Stress Tools Rafael Villager, Thomas Gordon Offshore Projects, USARoom C: 140 Strength Modeling Techniques for Extreme Pipeline Conditions Emily Norris Houston Dynamics, USARoom D: 198 Unique AI-Based Continuous Training Advances Patrick Turner Enbridge, Calgary, Canada |

| 17:00 | Conference Day 2 concludes |

Friday

| 7:00 | Breakfast |

| 7:00 | Registration open |

| 8:00 | Room A: 209 Gaining a Better Understanding of Hard Spot Threats: Summary of Findings From a Joint Industry Research Initiative Carlos Diaz, Rick Desaulniers ENTEGRA, Indianapolis, USARoom B: 252 Inspect the Unexpected: An Iterative Approach to Developing the Only NPS 4 1.5D Triaxial MFL Combo Tool William Deschamps-Robertson, McKenzie Kissel Onstream Pipeline Inspection, Calgary, CanadaRoom C: 279 The Benefits of ILI Signal Review Analyses in ILI Run-to-Run Comparisons — A Case Study Matt Ellinger, Andy Li, Stacy Hickey, Adriana Nenci, Pam Moreno, Ben Ross, Shanshan Wu DNV, Dublin, USA; Plains Midstream Canada, Calgary, Canada; DNV, Houston, USARoom D: 231 Complementary ILI Data-Driven Analysis to Identify the Interaction of Pipe Geohazards in Colombia’s Specific Geomorphological Conditions Lautaro Garin, David Classen, Oscar Gudinoan, Jaime Aristobat, Edwin Moreno Baker Hughes, Houston, USA; CENIT, Bogota, Colombia |

| 8:30 | Room A: 248 How Hard are Your Hard Spots? A Deep-Dive into the Subjective Nature of Hardness Measurements Atul Gangopty, Emmanuel Valencia, Debartha Bag ADV Integrity Inc., Magnolia, USA; Enbridge, Houston, USARoom B: 154 High-resolution Acoustic ILI: Introducing Triple-threat Detection and Sizing in a Single Pass Greer Simpson, Corey Richards, Carlos Costa, Aaron Schwing, Jeremy Hollifield, Jason Moritz DarkVision Technologies, North Vancouver, Canada; Flint Hills Resources, Wichita, USARoom C: 205 Identifying and Characterizing Corrosion Morphologies More Effectively with Tri-Axial MFL Signal Analysis Anthony Tindall, David Classen Baker Hughes, Houston, USARoom D: 166 Assessing Landslide Risk to Pipeline Installed by Horizontal Directional Drilling Using Inertial Measurements and Data Joel Van Hove, Owen Bunce, Peter Dowling, Peter Barlow BGC Engineering, Vancouver, Canada; Enbridge, Calgary, Canada |

| 9:00 | Room A: 278 Development of a High-Resolution Hard Spot Specification for Reliable Inline Inspection and Threat Management Cassidy Ryan, David Classen, Steve Farris, Oleg Shkarin, Austin Janousek Baker Hughes, Houston, USA; Enbridge, Houston, USARoom B: 263 Leveling up Axial Crack Evaluation with High-Resolution Acoustic Imaging Greer Simpson, Corey Richards DarkVision Technologies, North Vancouver, CanadaRoom C: 275 Methods for Consideration of ILI Measurement Tolerance Benjamin Mitchell, Terry DeLong, Matthew Nicholson, Brian Jimenez, Robert Zumd Dynamic Risk, Houston, USA; Enbridge, Calgary, CanadaRoom D: 148 Assessing Pipeline Geohazard Impact on Terrain-Based Failure Models Krishnanandukar, Ryan Milligan, Ravi Krishnamurthy Blade Energy Partners, Houston, USA |

| 9:30 | Room A: 256 The Development of Hard Spot ILI in an Era of Change Jason Edwards, Simon Slater, Ann Reo, Susan Moran ROSEN Group, Houston, USA; Williams, Tulsa, USARoom B: 109 Challenging ILI for SOUR Gas Service Pipelines Mussab Al-Nammi, Khalaf Al-Anazi, Mohammad Al-Rabeah Saudi Aramco, Dhahran, Saudi ArabiaRoom C: 183 The Value and Science Behind MDS Pro Assessment Techniques Dane Burden, Adrian Belanger, Ron Lundstrom, Miguel Maldonado T.D. Williamson, Salt Lake City, USARoom D: 108 Monitoring Pipeline Movement Using Magnetics-Based Technology: A Comparative Case Study Mehdi Lahoubi, Hamza Kella Benanni Skipper NDT, Paris, France; Enbridge, Houston, USA |

| 10:00 | Refreshment Break |

| 10:30 | Room A: 175 Trap Safety — Awareness of Normalization of Deviation Alan Morton, Jim Kay, Dick Williamson R.B. Williamson Energy Advisors, Tulsa, USARoom B: 254 Improvement of ILI Sizing Accuracy for Problematic Corrosion Profiles Pablo Cazeneuve, Katrina Jimenez, Ravi Krishnamurthy Blade Energy Partners, Houston, USARoom C: 178 Don’t Make Your Untaggable Pipeline Unpiggable Ken Maxfield, Jeffrey Knighton, Phil Tisovec ExxonMobil, Baton Rouge, USARoom D: 292 An Identity Crisis: The Impact of Manufactured Bends in Bending Strain Assessments Rhett Dotson, Alex Brown, Justin Taylor Integrity, Houston, USA |

| 11:00 | Room A: 110 Integrity Management Operations for Gas Operators in the Context of the EPA’s New Super-Emitter Program Douglas Sahm ZEVAC, Tulsa, USARoom B: 224 Managing Internal Corrosion Threat in Unpiggable Pipeline and Facility Deadlegs Leslie Ward Kiefner and Associates, Inc., Houston, USARoom C: 195 Bi-Directional Techtethered EMAT In-Line Inspections: A Case Study Travis Cast, Neil DeVettern Quest Integrity, Calgary, CanadaRoom D: 227 A Novel Method for Geospatially Mapping and Integrating ILI Bending Strain Data to Optimize Geohazard Threat Detection Sarah Newton, Caroline Scheerval BGC Engineering, USA |

| 11:30 | Room A: 162 Hide and Seek — The Games Pigs Play Alan Morton, Larry Alspaugh, Dick Williamson R.B. Williamson Energy Advisors, Tulsa, USARoom B: 168 Anomalous Weld Identification: Applying a Principal Component Analysis to Magnetic Flux Data Captured by Free-Floating ILI Tools Mike Byington, Anouk van Pol, John van Pol INGU Solutions, Houston, USARoom C: 122 Landslide Susceptibility Maps for Pipeline Geohazard Assessments Patricia Verde Geosynthetics Consultants, Canada |

| 12:00 | Conference concludes |

Are you looking for info for the PPIM 2026 Conference? The upcoming Pipeline Pigging and Integrity Management show will take place on January 19 – 22, 2026 at George R Brown Convention Center.

Find out more by clicking this link

Recent Comments